Maximizing Business Efficiency with 2000 kg Capacities in Vietnamese Electronics

In the rapidly evolving landscape of the Vietnamese electronics industry, achieving operational excellence is crucial for maintaining competitive advantage and fostering sustainable growth. Among the myriad factors that influence success, the ability to handle substantial loads efficiently — such as capacities around 2000 kg — plays a pivotal role. This article delves into how Vietnamese electronics enterprises optimize their manufacturing, logistics, and warehousing processes with 2000 kg solutions, highlighting best practices, innovative technologies, and strategic considerations that can elevate your business to new heights.

Understanding the Significance of 2000 kg Capacity in Vietnamese Electronics

Vietnamese electronics companies are increasingly adopting large load capacities to meet the demands of mass production, export requirements, and complex supply chains. The 2000 kg capacity benchmark represents a critical threshold, enabling businesses to handle sizable components, finished products, and raw materials with efficiency and safety. This capacity aligns with Industry 4.0 trends, emphasizing automation, precision, and sustainability.

The Role of 2000 kg Items in Electronic Manufacturing and Logistics

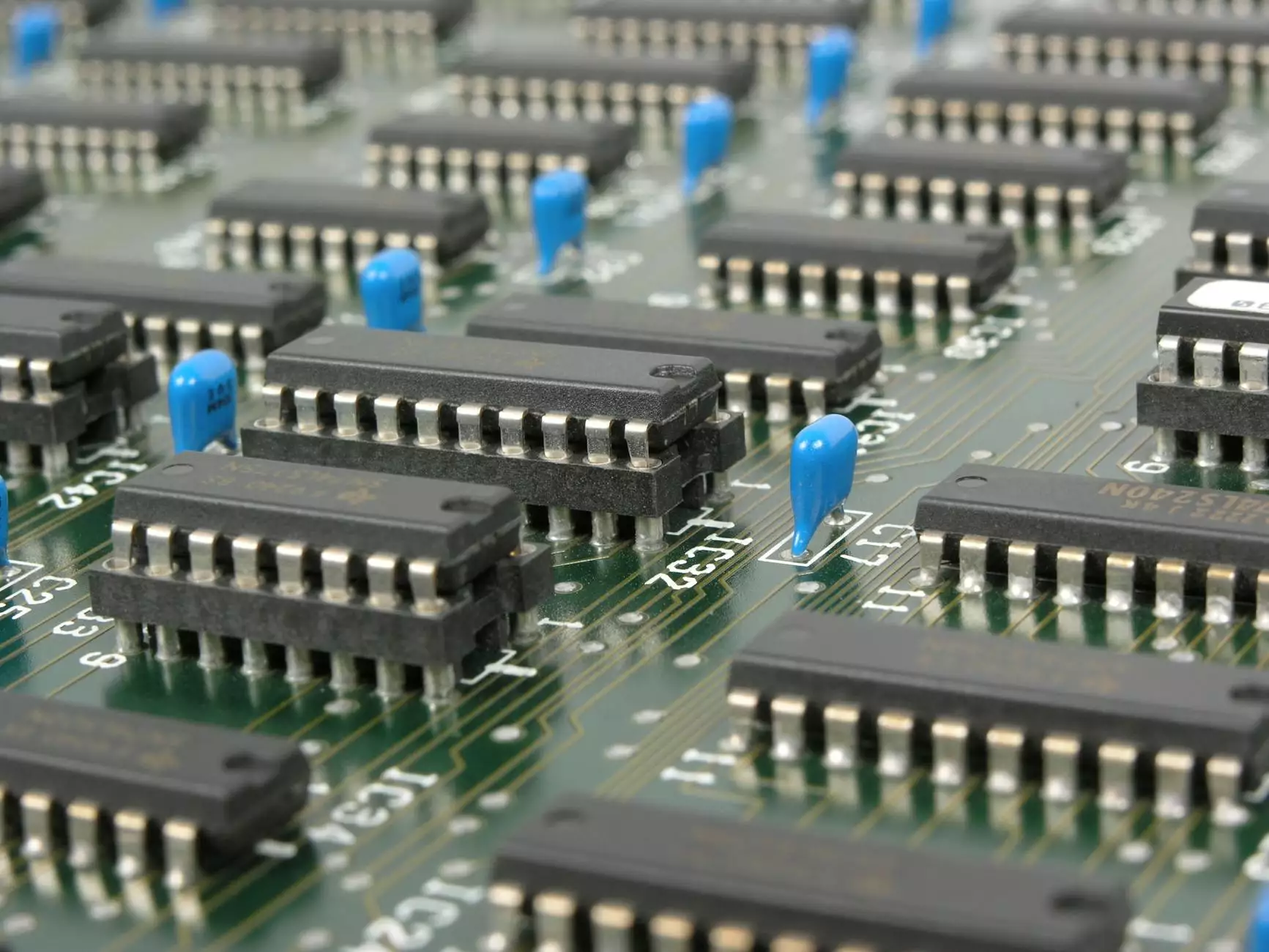

- Raw Material Handling: Managing bulky raw materials such as circuit boards, plastic casings, and electronic components requires robust lifting and transportation solutions capable of 2000 kg loads.

- Product Assembly: Large assembled units, like large-screen televisions, servers, and industrial equipment, often require handling capacities that surpass typical limits, making 2000 kg capacity equipment vital.

- Packaging and Shipping: Efficiently moving and stacking finished products weighing around 2000 kg ensures faster distribution and reduces logistics costs.

- Storage Solutions: Warehouse racking systems designed for high-density storage can comfortably handle 2000 kg load per shelf, optimizing space utilization.

Technological Innovations Supporting 2000 kg Capacity in Vietnamese Electronics

The technological landscape offers numerous breakthroughs tailored to enhance the handling of heavy loads such as 2000 kg. Adopting these innovations can significantly boost operational efficiency and safety.

Heavy-Duty Lifting Equipment and Cranes

Modern cranes, including gantry cranes and jib cranes, are designed to lift capacities of over 2000 kg. In electronics manufacturing plants, these cranes facilitate seamless movement of large components with precision, minimizing human error and maximizing safety.

High-Performance Material Handling Systems

Automated guided vehicles (AGVs) and robot-assisted handling systems are increasingly adopted by Vietnamese electronics firms. These systems are engineered to carry loads around 2000 kg and beyond, enabling continuous production lines with reduced downtime.

Robust Storage and Racking Solutions

Heavy-duty shelving systems with load capacities of 2000 kg per shelf allow for secure, space-efficient storage of bulky electronic parts and finished goods, reducing the risk of accidents and product damages.

Strategic Considerations for Incorporating 2000 kg Solutions

To maximize the advantages of handling 2000 kg loads, Vietnamese electronics companies should consider the following strategic factors:

Safety and Compliance

Ensuring safety standards align with local and international regulations is paramount. Regular training, routine maintenance, and adherence to safety protocols help prevent accidents related to heavy load handling.

Cost-Effectiveness

Investing in high-capacity equipment requires careful cost analysis. When integrated properly, the long-term savings in efficiency, reduced labor costs, and minimized product damages justify the initial expenditure.

Customization and Flexibility

Equipment that adapts to varied payload sizes and shapes provides greater flexibility, allowing them to accommodate diverse electronic components and finished products efficiently.

Environmental Sustainability

Choosing energy-efficient machinery and sustainable handling solutions supports Vietnam’s commitment to eco-friendly manufacturing practices, aligning business growth with environmental responsibility.

Case Studies: Vietnamese Electronics Companies Excelling with 2000 kg Capacities

ElectroTech Vietnam’s Logistics Transformation

ElectroTech Vietnam, a leader in electronics manufacturing, recently upgraded its logistics infrastructure with high-capacity cranes and storage units capable of handling 2000 kg. This transformation resulted in a 30% increase in warehouse throughput and a 20% reduction in handling time, illustrating the direct impact of capacity optimization on productivity.

Innovative Assembly Line at VietElectronics

VietElectronics integrated robotic handling systems designed for 2000 kg loads at their assembly plants. This upgrade enabled faster production cycles, greater precision, and improved worker safety, setting a new benchmark within the Vietnamese electronics sector.

Future Trends in Heavy Load Handling in Vietnamese Electronics Industry

- Automation and AI Integration: Leveraging artificial intelligence to optimize load management and predictive maintenance of heavy-duty equipment.

- Smart Warehousing: Implementing IoT-connected racking and storage systems capable of dynamically adjusting to load capacities around 2000 kg.

- Sustainable Heavy Machinery: Developing eco-friendly lifting and handling equipment that reduces energy consumption and minimizes environmental impact.

Conclusion: Unlocking Growth with 2000 kg Capacity Solutions

Vietnamese electronics enterprises that invest in 2000 kg load capacity technology not only streamline their operations but also position themselves at the forefront of innovation and efficiency. By understanding the importance of robust, scalable, and safety-compliant handling systems, businesses can meet increasing market demands, improve product quality, and achieve sustainable growth in a competitive global landscape.

As the industry evolves, embracing advanced capacity solutions will become an essential strategy for Vietnamese electronics companies aiming to expand their footprint, enhance operational resilience, and deliver superior value to customers worldwide.