CNC Machine Manufacturers: Advancing the Metal Fabrication Industry

The CNC machine manufacturers industry is a cornerstone of modern manufacturing, playing a vital role in the metal fabrication sector. Computer Numerical Control (CNC) machines have revolutionized how parts are created, maintaining a precision and efficiency that manual processes can no longer match. In this comprehensive article, we will delve deep into the advancements, benefits, and future of CNC machinery, especially for metal fabricators.

Understanding CNC Machining

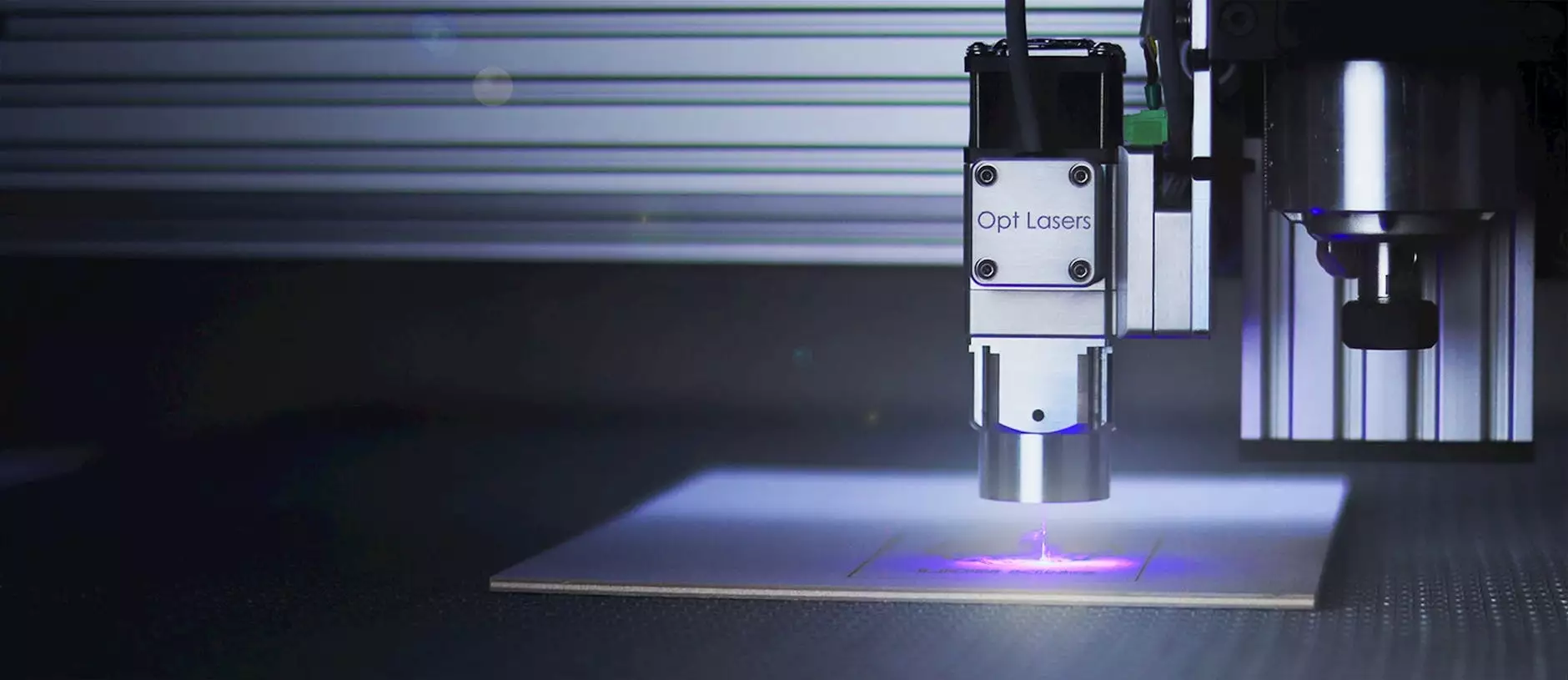

CNC machining is a technology that utilizes computers to control machine tools. These machines can create complex shapes directly from computer-aided design (CAD) files. The process allows for greater accuracy, reduced waste, and increased speed in production.

Key Components of CNC Machines

To better understand the role of CNC machine manufacturers, it's essential to know the key components of CNC machines:

- Computer System: The brain of the CNC machine. It executes the programmed instructions.

- Drive Mechanism: Converts the computer signals into mechanical movement.

- Machine Tool: The physical component that shapes the metal, which varies from lathes to mills.

- Feedback System: Monitors the machine's performance and ensures accuracy.

The Role of CNC Machine Manufacturers

CNC machine manufacturers design and assemble the machines that drive the manufacturing industry. These manufacturers are responsible for the continuous innovation in CNC technology that leads to improved performance and efficiency in metal fabricators.

Innovation in CNC Technology

Innovation is at the heart of CNC machine manufacturing. Here are some of the recent advancements:

- High-Speed Machining: Allows for faster operations without compromising the quality of finished products.

- Multi-axis Machining: Enables the cutting tool to move on multiple axes (usually three or five), allowing for more complex geometries.

- Automated Tool Change: Streamlines the production process by allowing the machine to switch tools automatically as needed.

- Integration with IoT: Smart CNC machines can connect to the Internet of Things, providing real-time data for better monitoring and controls.

Benefits of CNC Machining for Metal Fabricators

Partnering with CNC machine manufacturers brings numerous benefits for metal fabricators. Let’s explore some of them:

Precision and Accuracy

One of the greatest advantages of CNC machines is their unmatched precision. They can produce parts within thousands of an inch, which is crucial for industries requiring exact specifications, such as aerospace and medical.

Increased Production Speed

CNC machines significantly enhance production speed. Manufacturing processes that might take hours with traditional machines can often be completed in much less time—enhancing throughput and productivity.

Reduced Labor Costs

With the automation of manufacturing processes, fabricators can decrease labor costs. Instead of requiring multiple skilled operators, CNC machines can often be run by a single technician who monitors operations and manages quality control.

Flexibility in Production

CNC machines can easily be reprogrammed to produce different parts without extensive setup changes, providing metal fabricators with the flexibility to adapt to market demands rapidly.

Applications of CNC Machining in Metal Fabrication

CNC technology is utilized across various sectors in the metal fabrication industry. Some notable applications include:

- Medical Equipment Manufacturing: Strict tolerance requirements make CNC machining essential for producing surgical instruments and implants.

- Aerospace Components: Components for aircraft require precision and strength, making CNC machining the preferred choice.

- Automotive Parts: The automotive industry benefits from high-speed production and micro-manufacturing capabilities.

- Tool and Die Making: CNC machining plays a critical role in creating molds, dies, and tooling for various manufacturing processes.

Choosing the Right CNC Machine Manufacturer

When selecting a partner among CNC machine manufacturers, several factors need consideration. Here are key criteria that can guide your decision:

Experience and Reputation

Assessing a manufacturer's experience in the industry is vital. Look for companies with a solid track record and positive feedback from previous clients. Online reviews and industry referrals can provide insight into their reputation.

Quality of Machinery

Quality is paramount when it comes to CNC machines. A good manufacturer will use high-grade materials and thorough testing to ensure durability and performance.

Customer Support and Training

Choose a manufacturer that offers comprehensive customer support and training services. This will ensure that your team can operate the machines safely and efficiently, maximizing productivity from the start.

Customization Options

Every metal fabrication business has unique needs. A manufacturer offering customization options can better meet your specific requirements and improve your operational efficiency.

The Future of CNC Machining

The future of CNC machining in the metal fabrication industry looks promising. With technological advancements such as AI and machine learning, the efficiency and capabilities of CNC machines are expected to expand even further.

Artificial Intelligence and Machine Learning

AI integration is set to revolutionize CNC machining. Machines that can learn from production data and optimize themselves for maximum efficiency will reduce downtime and enhance quality control.

Green Manufacturing

As sustainability becomes more critical, CNC machine manufacturers are focusing on eco-friendly practices. This includes reducing energy consumption, material waste, and embracing recycled materials in the production process.

Industry 4.0 and Smart Factories

The concept of Industry 4.0, which focuses on smart factories, is increasing the interconnectivity of devices, machines, and systems. CNC machine manufacturers are at the forefront of this integration, ensuring that machines can communicate efficiently for optimized production flows.

Conclusion

The significance of CNC machine manufacturers in the metal fabrication industry cannot be overstated. As these companies continue to innovate and adapt, they will play an essential role in shaping the future of manufacturing. Metal fabricators must stay informed and partner wisely to leverage the full potential of CNC technology. With the right CNC machines, businesses can boost their productivity, enhance precision, and remain competitive in a rapidly evolving market.